Zoom

Zoom

Zoom

Zoom

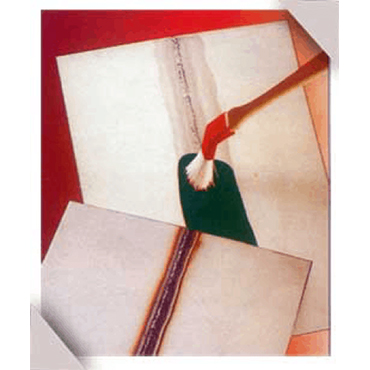

This is like a thick paste applied with a brush to descale the heavy weld scales. It removes discolourations, heat marks, annealing colors, rust particles in and around the welding area caused due to heat evolution during welding. "K-2" paste coverss 90-100 metres of weld seams in 1 kg. of chemical.

HOW TO APPLY K-2 PASTE

- 1. Removal of oil - SI- 56 (Soak cleaner, powder - 50 gm/lit.)

- 2. K-2 paste is to be applied on the weld seam & surrounding area with a brush.

- 3. Leave the K-2 paste on the weld seam for 30-45 minutes depending on the thickness of the oxide scale.

- 4. Brush the surface with a plastic bristled brush and then wash surface thoroughly with water.

- 5. Next apply K-2 passivation solution and and leave it for 20-25 minutes.

- 6. Finally clean the surface thoroughly with water.

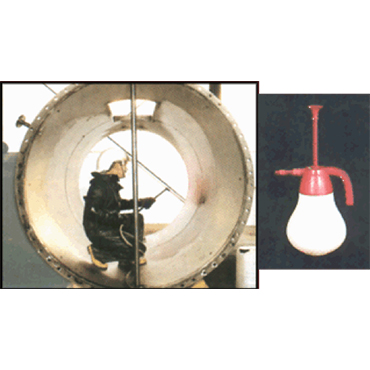

This is a semi-gel type of chemical and is used to pickle & passivate large surface area with a spray pump. It also simultaneously removes annealing colours, ferritic contamination and weld burns. "K-2" spray is very safe, convenient and easy to use for cleaning large vessels, agitators, tankers, boilers, heat exchangers pressure vessels, storage tanks etc. It also restores the Mill finish. This form of "K-2" cleans 40 - 50 sq ft.area with 1 kg. of chemical.

HOW TO APPLY SPRAY FORM

- 1. Removal of oil - SI-56 (Soak cleaner, powder - 50gm/lit.)

- 2. K-2 spray is to be sprayed on the S. S. surface with a pressurised plastic spray bottle or spray pump.

- 3. After spraying leave it for 30-60 minutes.

- 4. Then wash the surface thoroughly with water.

- 5. Next apply K-2 passivation solution and leave it for 20-30 mins.

- 6. Finally rinse the surface thoroughly with water.