Zoom

Zoom

Zoom

Zoom

Zoom

Zoom

Zoom

Electro Plating Equipments & Jigs nvolved into manufacturing of Equipments required for Electro Plating & Electrophoretic Lacquer, powder coating, anodizing industries since last 2 decades. Following are the details of the manufacturing activities:

1) Plating Plants

- a) Fully Automatic Plants

- b) Semi Automatic Plants

- c) Modular Plants

- d) Manual Plating Plants

- e) Electrophoretic Ultra filtration System with TRAP.

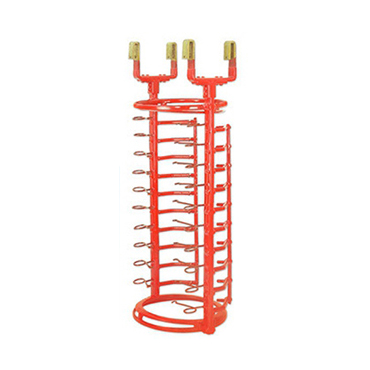

2) Racks for various applications

- a) PCB, Automotive, Decorative, Builder Hardware, Anodizing etc.

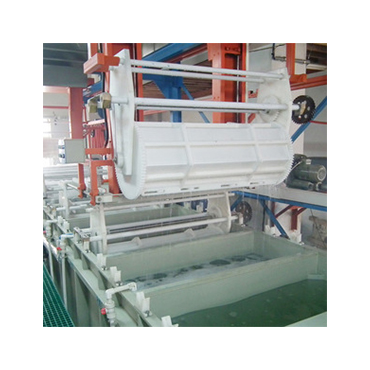

3) Barrels

- a) Fully submerged Barrel

- b) Hanger Type barrel

- c) Barrels for small electronic components (In association with tscherwitschke GmbH, Germany)

- d) Manual Plating Plants

4) Plating Plant Accessories

- a) PP Tank

- b) MS Lead bonding Tank for Anodizing.

- c) SS Tank

- d) Magnetic Filters (Different capacities)

- e) Dryers (Different capacities) (2 Kg. to 50 Kg.)

5) Small Plant System for Jewelery

- a) Table Top Model Plant for Rhodium

- b) Pen Plating Unit

6) Mass Finishing Equipment

- a) Vibratory Polishing Unit (3 in 1).

- b) Circular Vibrators -100 Ur. To 1200 Ur.

- c) Centrifugal Disc Finishing Machine

- d) Magnetic Filters (Different capacities)

- e) Mini Drag Finishing Machine (In association with Walther Trowal, Germany.)

7) Pickling Plant, Effluent Treatment Plant

8) Lab Equipments

- Hull cell (ordinary)

- Hull cell with heater Andenergy control

- Chrome Testing Hull Cell

- Sulphate Testing Kit

- Salt Spray unit

- Acrylic / PP

- Acrylic

- PVC

- For accurate determination of sulphate in chrome bath.

- Acrylic