Fevikwik GP

Bonds Rubber

Bonds metal to rubber

Bonds PLastic

fevikwik Gel

Fix Name Plate

- a) Colorless

- b) Solvent-Less

- c) Fast Setting

- d) Ease of application

- e) Medium viscosity

Application Areas

Fevikwik GP is suitable for bonding plastics, metal and rubber components. It has typical applications in molded furniture, sign boards, gift articles, besides this it is also used for wide range of industrial applications

Technical Parameters

| Appearance | Clear transparent liquid | |

| Viscosity at 25oC | 40 to 70 cps (approx) | |

| Flash Point | >85oC | |

| Tensile Shear Strength | >100 Kg/sq.cm | |

| Full curing | 24 Hours at ambient | |

| Operating temperature | (-) 40 to 80oC | |

| Specific Gravity | 1.06(approx) | |

| Cure Speed (Approx) It does not bond PE, PP and PTFE | Metal to Metal | <20 Seconds |

| Plastics to plastics | <10 Seconds | |

| Rubber to rubber | <5 Seconds | |

Available in: 20 g

- a) Colorless

- b) Solvent-Less

- c) Controlled flow

- d) Longer adjusting time

- e) Suitable for vertical application

Application Areas

Fevikwik Gel is suitable for bonding wood, metal and rubber leather, cardboard and most plastic components. It has typical application molded furniture, sign boards, gift articles, besides this it is also used for wide range of industrial applications.

Technical Parameters

| Appearance | Clear transparent liquid | |

| Viscosity at 25oC | 1500cps (approx) | |

| Flash Point | >85oC | |

| Tensile Shear Strength | >80 Kg/sq.cm | |

| Full curing | 24 Hours at ambient | |

| Operating temperature | (-) 40 to 80oC | |

| Specific Gravity | 1.06(approx) | |

| Cure Speed (Approx) It does not bond PE, PP and PTFE | Metal to Metal | <20 Seconds |

| Plastics to plastics | <10 Seconds | |

| Rubber to rubber | <10 Seconds | |

Available in: 3 g, 20 g

Steelgrip Insulation Tape

Stop Sort Circuiting

Stop Arcing

Provide Insulation

- a) Conforms to IS: 7809 (Part 3, Sec 1)

- b) Self extinguishing

- c) Protects from electrolytic corrosion

- d) Excellent water resistance

- e) Suitable for primary insulation up to 440V

Application Areas

Used in electrical insulation of wire joints in single and three phase wiring. It is used for insulation of wire joint of decorative lights, fans, home appliances, all kinds of electrical motors, resistors, capacitors, electrical circuits, transformers etc.

Technical Parameters

| Colour | Black, Blue, Yellow, Green and Red |

| WidthoC | As specified |

| Length | As specified |

| Total thickness of tape (mm) | 0.1 to 0.15 |

| Adhesion to steel (N/10mm width) | 1.6 Minimum |

| Adhesion to backing (N/10mm width) | 1.3 Minimum |

| Tensile strength (N/10mm width per mm thickness) | 150 Minimum |

| Electrical Strength at RT (kV/mm) | 40 Minimum |

| Electrical Strength at after humid condition (kV/mm) | 35 Minimum |

| Insulation resistance (Ohms) | 1x1011 Minimum |

Available in: 1.8cmx3m, 1.8cmx7m, 1.25cmx9m, 1.9cmx25m

Colours available: Red, Green, Blue, Black, White and Yellow.

Acetoxy/Natural Cure

Seal & Insulate

Seal & Fills Gap

Seal & Fills Gap

- a) Single Component RTV

- b) Acetoxy cure

- c) Excellent flexibility with anti sag property

- d) High temperature resistance

Application Areas

Ideal for Sealing glass and aluminium frame joints,Seal cracks around window, ducts, fixture etc. Crack filling in RCCs, infrastructure designs, joint sealing in wash basins, kitchen sinks etc.

Technical Parameters

| Colour & appearance | Clear, White, Black Paste |

| Specific Gravity at 30oC | 0.92 to 0.99 |

| Skin formation time at 30oC | 5 to 20 minutes |

| Curing speed at 30oC | 3mm per day |

| Hardness (Shore A after 7 days cure) | 16 to 25 |

| Elongation at break | 375% minimum |

| Paintability | Not paintable |

| Temperature resistance | 60oC to 180oC |

Available in: 280 ml Cartridge

Also available: Applicator Gun

- a) Single Component

- b) Natural cure

- c) Excellent adhesion to glass, metal & ceramics

- d) Non-corrosive

- e) Non-sag

- f) No mixing required

- g) Free from bad smell

Application Areas

Ideal for bonding mirror hanging fixture, gap filling. Can be applied on vertical and overhead joint and wide range of industrial uses.

Technical Parameters

| Colour & appearance | Clear, Black homogeneous Paste |

| Flow/sag at ambiant temprature | Nil |

| Skin formation time at 30oC | 5 to 20 minutes |

| Curing speed at 30oC | 3mm per day |

| Elongation at break | 250% minimum |

| Paintability | Not paintable |

Available in: 280 ml clear & black variants

Also available: Applicator Gun

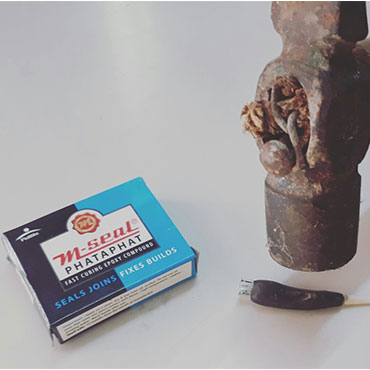

M-Seal General/Phataphat

Builds

Seal

Insulates

- a) Two component epoxy putty

- b) Set in 90 minutes

- c) Excellent Chemical resistance

- d) Excellent Insulation resistance

- e) It can be machined to desired shape

Application Areas

Ideal for sealing blow holes, cracks in metal casting, pumps, moulds, wooden patterns. Sealing of leakage in tank, vessel, boiler, heat exchanger, pipelines, gear boxes, cooling towers etc. It is also used for insulation of cable terminals, cable entry into switch boxes

Technical Parameters

| Working time at 30oC for 50g mix | 15 to 20 minutes |

| Setting time at 30oC for 30g mix by Shore A | 60 to 90 minutes |

| Tensile Strength as per ASTM D 638 | More than 200kg/cm2 |

| Compressive Strength as per ASTM D 695 | More than 400kg/cm2 |

| Hardness Shore D as per ASTM D2240 | More than 75 |

| Overlap shear strength as per ASTM D1002 | More than 90kg/cm2 |

| Water absorption as per ASTM D 570 | Below 0.5% |

| Service temperature limit | 80oC |

Available in: 250 g, 1kg and 4kg

- a) Two component epoxy putty

- b) Set in 30 minutes

- c) Excellent Chemical resistance

- d) Excellent Insulation resistance

- e) It can be machined to desired shape

Application Areas

Ideal for sealing blow holes, cracks in metal casting, pumps, moulds, wooden patterns. Sealing of leakage in tank, vessel, boiler, heat exchanger, pipelines, gear boxes, cooling towers etc. It is also used for insulation of cable terminals, cable entry into switch boxes

Technical Parameters

| Working time at 30oC for 50g mix | 15 to 10 minutes |

| Setting time at 30oC for 30g mix by Shore A | 30 minutes |

| Tensile Strength as per ASTM D 638 | More than 200kg/cm2 |

| Compressive Strength as per ASTM D 695 | More than 400kg/cm2 |

| Hardness Shore D as per ASTM D2240 | More than 75 |

| Overlap shear strength as per ASTM D1002 | More than 70kg/cm2 |

| Water absorption as per ASTM D 570 | Below 0.5% |

| Service temperature limit | 80oC |

Available in: 1kg